Tel/Whatsapp:+86 13423078888

E-mail:chloe_mo@wchtemperglass.com

Address:Yuan He Road North, Xiang Xi Industrial Zone, Shipai Town, Dongguan City, Guangdong Province, China

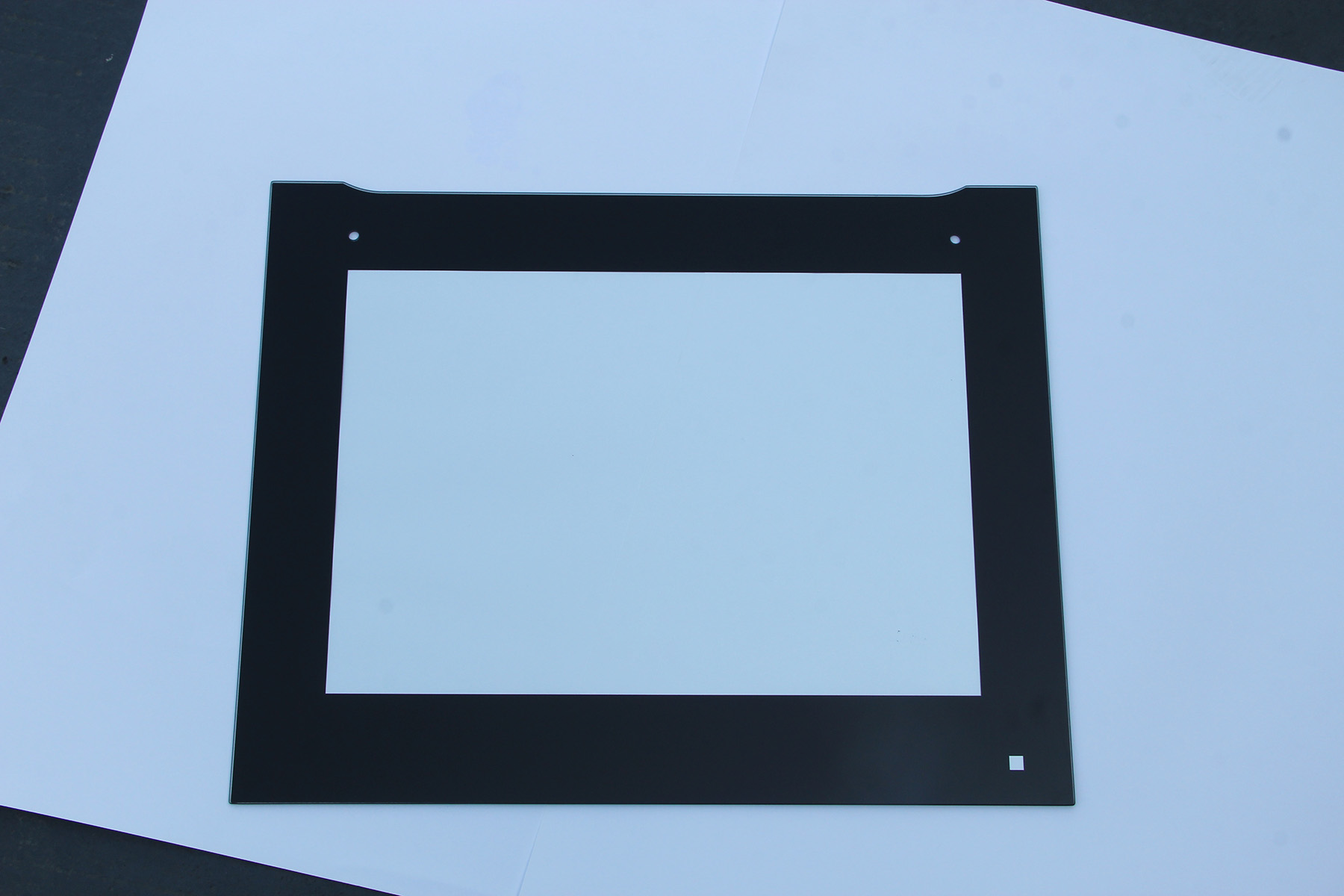

The Low-E Glass Front Door is a high-performance glass solution specially engineered for household appliances such as ovens, microwave ovens, steam ovens, and built-in kitchen equipment. Compared with traditional tempered Oven Glass, Low-E (Low-Emissivity) coating significantly reduces radiant heat transfer, enhances thermal efficiency, and keeps the outer glass surface cooler and safer during operation.

Our Low-E oven glass series includes:

Low-E Glass Front Door

Low-E Oven Glass Panel

Glass Oven Door Low-E

Tempered Low-E Oven Glass

Heat-Resistant Low-E Glass

Best Low-E Glass for Oven Door

These panels are made from high-strength tempered glass or heat-resistant laminated glass, optionally available in single-pane, double-pane, or triple-pane constructions depending on customer requirements.

Material: Tempered glass / Heat-resistant laminated glass

Type: Single, double, or triple-pane Low-E structure

Thickness: 3.2mm / 4mm / 5mm / customized

Coating: High-temperature Low-E coating (Low-E 180 optional)

Color: Transparent, black, grey, smoked, customized colors

Temperature Resistance: 250°C – 700°C depending on material

Edge Processing: Polished edges, CNC cut, rounded corners

Surface Options: Silk printing, IR coating, anti-explosion film

Application: Oven door glass, microwave door, built-in oven panel, steam oven glass

The Low-E coating reflects infrared heat back into the cooking chamber, improving heating efficiency while reducing heat loss through the glass for oven door structure.

Because Low-E reduces radiant heat emission, the outer tempered glass front door stays noticeably cooler during baking or grilling, improving safety for families, especially households with children.

Made from tempered oven glass, the panel withstands rapid temperature changes without cracking—ideal for high-temperature appliances.

Available in double-pane and triple-pane designs to enhance energy efficiency and maintain stable internal oven temperature.

High-quality Low-E coating maintains clarity and reduces buildup of smoke and grease.

Includes printing, thickness, shape, transparent area, viewing window design, and more to match appliance branding.

We specialize in oven door glass, microwave inner door panels, and other kitchen appliance glass components, ensuring solutions tailored for high-temperature environments.

Our coatings provide stable performance even after prolonged heating cycles, outperforming standard architectural Low-E glass.

Every glass panel is cut and polished using advanced CNC machines, ensuring perfect fit and smooth, safe edges.

We support OEM/ODM for brands worldwide, providing structural engineering, thermal calculations, and glass simulation testing.

Each batch undergoes tempering tests, thermal shock tests, impact tests, adhesion tests, and coating durability tests.

Direct manufacturing ensures cost-effective solutions with premium quality.

Our Low-E glass products are suitable for a wide range of kitchen appliances:

Built-in oven glass doors

Microwave oven glass front door

Steam oven front door panel

Electric oven and toaster oven

Commercial bakery ovens

Combination oven/microwave appliances

We offer fully customized Low-E oven glass solutions:

Glass size, thickness, and shape

Single / double / triple-pane Low-E structure

Customized viewing window

Silk printing pattern, color, and logo

High-temperature ceramic printing

Optional Low-E 180 coating for superior energy efficiency

Special coating (anti-reflection, anti-smudge, IR coating)

Explosion-proof film or laminated safety structure

Our products meet international appliance-industry standards:

IEC 60335 safety requirements

RoHS & REACH environmental compliance

Tempering stress testing and fragmentation test

Thermal shock resistance tests (up to 250–700°C)

Coating adhesion and durability testing

Optical & emissivity inspection for each panel

Individual protective film + foam corners

Multi-layer export-grade cartons

Wooden crate for long-distance or container shipments

Safe separation for multi-pane glass

Custom pallet packaging available

15–25 days lead time depending on order quantity

Low-E (Low-Emissivity) glass has a special coating that reflects infrared heat back into the oven, reducing heat loss and improving cooking efficiency.

Yes. Our Low-E oven glass uses high-temperature-resistant coating and tempered substrate specially developed for cooking appliances.

Tempered glass provides strength, while Low-E adds thermal efficiency by controlling heat radiation.

Yes. We supply single, double, and triple-pane Low-E structures for premium ovens with enhanced insulation.

Absolutely. We can customize printing, structure, coating type, glass shape, and more according to your appliance design.

Low-E 180 is an advanced Low-E coating with excellent emissivity control, ideal for improving oven efficiency and reducing heat loss.

Yes. Send us drawingsor samples—we can produce exact replacements or improved designs.

Yuan He Road North Xiang Xi Industrial Zone Shipai Town Dongguan City