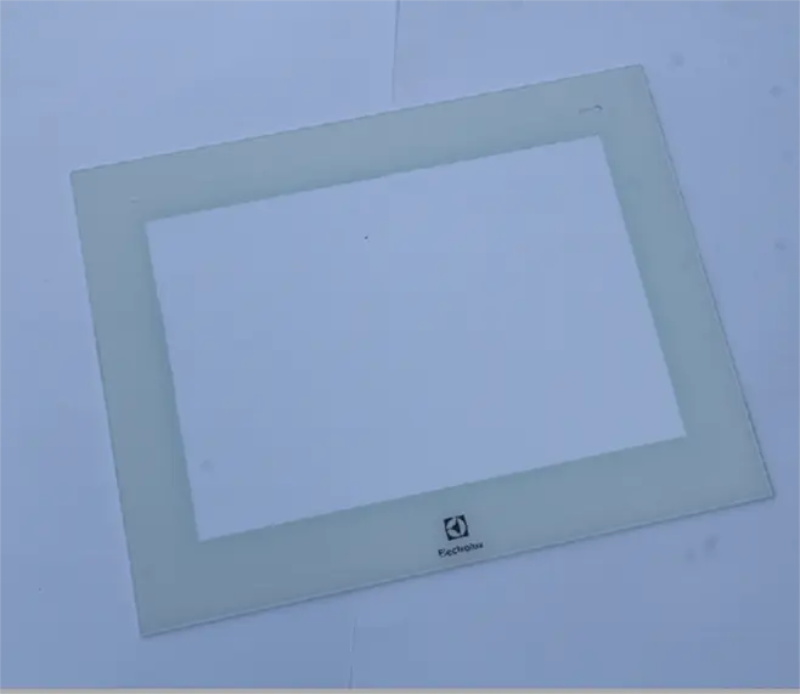

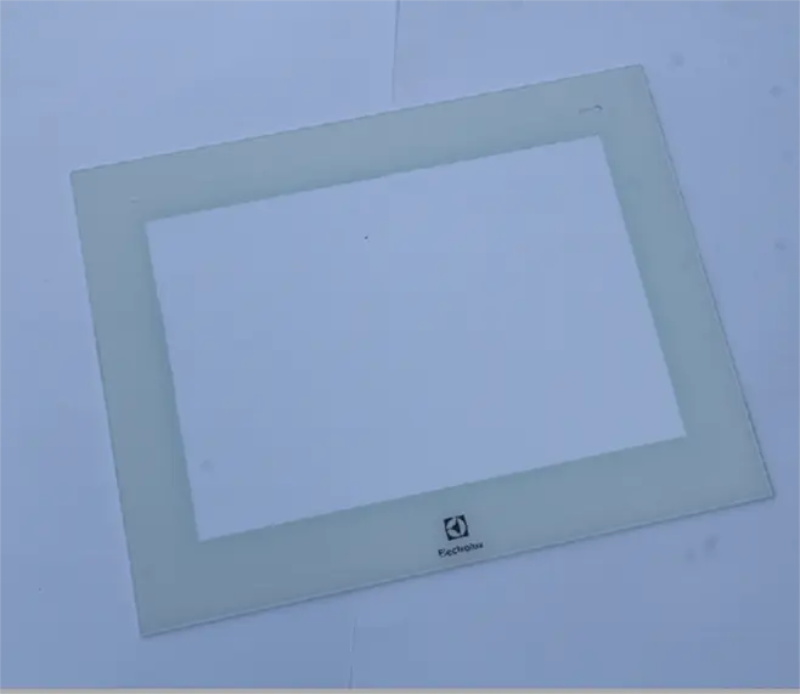

There will be errors more or less during the processing of Tempered Glass. It is normal for the error to be within plus or minus 2mm. If the glass error exceeds plus or minus 2mm, the staff must check what causes the large error in the glass. Let me introduce to you What are the reasons for errors in glass deep processing? 1. Clamping error: The error generated during the clamping process of the workpiece is called clamping error. Clamping error includes positioning error and clamping error. 2. Measurement error: For example, the measurement error of Oven Door Glass is an error related to the measurement principle, manufacturing accuracy, measurement conditions (temperature, humidity, vibration, measurement force, cleanliness, etc.) of measuring tools and measuring instruments, and the level of measurement technology. 3. Adjustment error: The main function of adjustment is to make the tool and workpiece reach the correct relative position. The adjustment error of the trial cutting method mainly depends on the measurement error, the feed error of the machine tool and the force deformation of the process system. In addition to the above factors, the adjustment error during processing by the adjustment method is also related to the adjustment method. 4. Manufacturing, installation errors and wear of fixtures: The processing and assembly errors of positioning elements, guide elements, tool setting elements, indexing mechanisms, clamp bodies, etc. on machine tool fixtures, as well as their wear resistance, have an impact on the machining accuracy of parts. direct impact. The accuracy requirements of the fixture should be determined according to the machining accuracy requirements of the workpiece. 5. Manufacturing error and wear of cutting tools: The influence of cutting tools on machining accuracy varies with different types of cutting tools. 6. Workpiece error: Before machining, the shape error of the surface to be processed on the workpiece or blank or the position error of its related surface will also cause the machining error of the surface itself and its related surface after machining. 7. Machine tool error: Manufacturing and installation errors of machine tools and wear after long-term use are the main original error factors that cause machining errors. Machine tool errors are mainly composed of spindle rotation errors, guide rail guidance errors, transmission errors of internal transmission chains, and positional relationship errors between spindles and guide rails. 8. Errors caused by thermal deformation of the process system: In machining, the process system will be deformed by the influence of cutting heat, friction heat, ambient temperature, radiant heat, etc., which will destroy the correct relative position of the workpiece and the tool, causing cutting movement , The amount of back-cutting and cutting force changes, resulting in processing errors. 9. The error caused by the residual stress of the workpiece: In the absence of external force or after the removal of external force, the force remaining in the workpiece is called residual stress. For parts with residual stress, the equilibrium state of the internal structure is extremely unstable, and there is a strong tendency to return to a stress-free state.

This is the reason for the error in almost all possible White Goods Glass processed products summarized by the editor. No product will be perfect, and the glass product is the same. What we have to do is to make the product closer to perfection. Therefore, the error allowed by the country for glass processed products is plus or minus 2mm. If the error exceeds this error, you should find the above reasons.